Comprehending the Significance of Foam Control in Food and Drink Processing

Comprehending the Significance of Foam Control in Food and Drink Processing

Blog Article

A Comprehensive Overview to Executing Foam Control Solutions in Your Operations

Efficient foam control is a crucial aspect of functional efficiency that usually goes ignored. Recognizing the complexities of foam generation can considerably affect both efficiency and item high quality. By checking out key variables such as application compatibility and employees training, companies can maximize their foam administration efforts.

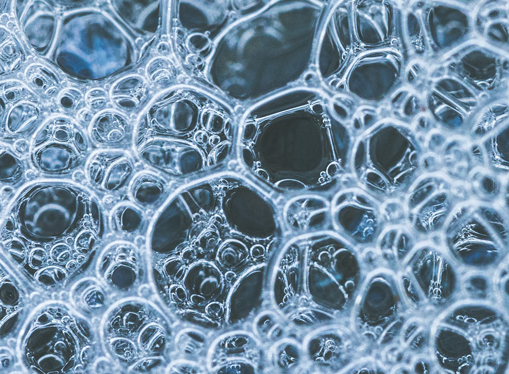

Comprehending Foam Difficulties

Foam challenges are a substantial worry throughout different industries, influencing operational performance and item high quality. The formation of excessive foam can impede procedures such as mixing, transportation, and storage space, resulting in boosted downtime and waste. In industries like food and drink, drugs, and petrochemicals, foam can hinder production lines, causing product inconsistencies and contamination threats.

Moreover, foam can obstruct devices performance, bring about pricey repair services and maintenance. In wastewater therapy, foam can interfere with clarifier operations, resulting in lower treatment performance and governing compliance problems.

Comprehending the underlying root causes of foam generation is important for reliable administration. Variables such as surfactants, temperature changes, and frustration levels can all contribute to foam production. Recognizing these elements permits industries to carry out targeted approaches that reduce foam development while keeping product stability.

Kinds Of Foam Control Solutions

Mechanical remedies entail the usage of tools such as foam skimmers or defoamers. Chemical options, on the various other hand, include the application of defoaming agents-- substances that disrupt the foam framework, leading to its collapse. Foam Control.

Lastly, functional techniques concentrate on procedure adjustments. This might include changing devices criteria, such as temperature level and pressure, or altering the circulation prices of liquids to minimize foam generation. Implementing great housekeeping techniques can likewise reduce foam development by reducing impurities that contribute to foam stability.

Picking the suitable foam control service involves analyzing the specific requirements of the procedure, consisting of the sort of procedure, the attributes of the products included, and security factors to consider.

Picking the Right Products

Picking the appropriate foam control products requires a detailed understanding of the certain application and its distinct challenges. Aspects such as the type of foam, the atmosphere in which it occurs, and the desired outcome all play critical duties in product choice. Foam Control. For example, in industries like food processing, it is necessary to pick food-grade defoamers that follow safety and security laws while properly managing foam.

Additionally, think about the thickness of the liquid where the foam trouble exists. Some products are developed for low-viscosity applications, while others are customized for thicker fluids. Compatibility with existing processes is an additional vital aspect; the chosen foam control agents should incorporate flawlessly without interrupting total procedures.

Another vital element is the method of application. Some items might require dilution, while others can be applied straight. Evaluating the convenience of usage and the required dosage can provide insights right into the product's performance and cost-effectiveness.

Application Strategies

Successful implementation techniques for foam control solutions need an organized technique that straightens item option with functional requirements. The initial step includes a detailed evaluation of the procedures where foam happens, determining particular areas that necessitate intervention. By engaging cross-functional teams, consisting of high quality, manufacturing, and engineering assurance, organizations can gather insights that notify the option of the most reliable foam control products.

Following, it is vital to develop clear objectives for foam reduction, making certain that YOURURL.com these goals are quantifiable and achievable. This might involve specifying appropriate foam levels and the timelines for execution. Training personnel on the properties and application methods of picked foam control representatives is similarly vital, as appropriate use is important for optimum results.

Furthermore, integrating foam control solutions into existing workflows calls for mindful planning. Eventually, a well-structured approach will certainly enhance operational performance while effectively handling foam-related difficulties.

Surveillance and Examining Effectiveness

Tracking and reviewing the efficiency of foam control options is important for making certain that executed strategies produce the desired outcomes. This procedure entails systematic information collection and analysis to analyze the performance of foam control agents and techniques. Trick performance signs (KPIs) need to be developed prior to execution, allowing for a clear baseline against which to measure progress.

Examining effectiveness also needs periodic reviews of foam control treatments and representative efficacy. This can be accomplished with tasting and screening, allowing operators to figure out if current solutions are satisfying operational needs. It is important to obtain comments from team members who engage with these systems daily, as their understandings can expose functional nuances that measurable data might forget.

Eventually, an organized monitoring and analysis framework helps identify necessary changes, making sure that foam control options remain effective, cost-efficient, and straightened with organizational goals.

Conclusion

Finally, effective foam control options are important for maximizing functional effectiveness and keeping product top quality. A detailed understanding of foam difficulties, combined with the selection of ideal products and implementation methods, facilitates the successful management of foam generation. find out here Spending and establishing quantifiable kpis in personnel training additionally boost the effectiveness of foam control procedures. Routine monitoring and examination ensure constant renovation, eventually causing a more productive and structured functional atmosphere.

Implementing great housekeeping methods can likewise reduce foam formation by decreasing pollutants that contribute to foam security.

Selecting the ideal foam control items requires a complete understanding of the details application and its one-of-a-kind challenges (Foam Control).Effective application methods for foam control services need a systematic strategy that lines up product selection with operational needs.In verdict, Extra resources efficient foam control services are necessary for enhancing operational effectiveness and maintaining product top quality. A comprehensive understanding of foam challenges, integrated with the option of suitable items and application techniques, assists in the successful management of foam generation

Report this page